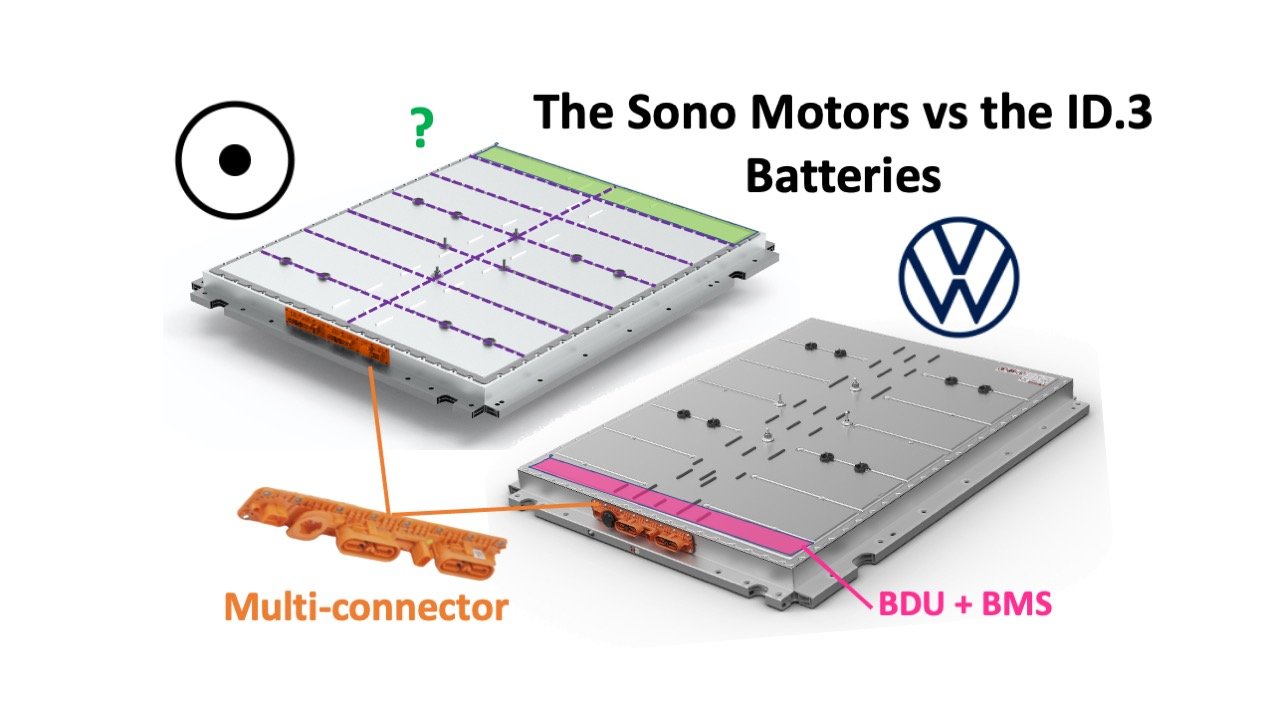

The Sono Motors vs the Volkswagen ID.3 Batteries

Sono Motors (left) and VW ID.3 (right) Battery Packs. Image credit: Sono Motors (left) and Volkswagen ID.3 (right)

I love studying Battery Pack and I deeply care about the details in the Battery Packs because a lot of the Technology is embedded in the way Battery cells are put together. I have quite a good memory and when I opened the image of Sono Motors Battery Pack for the 1st time, I had to make sure that I did not look at the Volkswagen website!

I have tried to search for information about any link between Sono Motors and Volkswagen in the development of the Battery Pack but did not come up with anything…so I decided to write this “interesting” comparison myself…

Let’s start with a side by side comparison of the global packs. Showing the 2 packs next to each other do not need much more explanation to know why I am interested in this comparison….

One particularity about the VW ID.3 Battery Pack is that they use a one-piece housing connector with following connections:

2 charging connections (1 for AC and 1 for DC)

1 connection for the inverter

1 connection for the Electronics (low voltage)

In addition, this multiple-connector also integrates a venting (OROVEL Card EV38).

Of course, such a connector simplifies the wiring/cabling within the Battery Pack. It also allows reducing the assembly effort and the logistic as a single-part replaces a set of connectors of various sizes and shapes.

Before looking at the Sono Battery Pack, I have never seen this multiple port used in any other pack that the VW ID.3.

Explanation of the VW ID.3 Module organisation. Left: embossment of the module separator on the Battery Top Cover. Right: explanation of the organisation of the modules (config 77 kWh) and well as the electronics (BDU + BMS)

Observing a Battery Cover is also very useful to learn about the Battery architecture. For example, on the VW ID.3, the top cover shows some sort of “line-embossment” where the physical separators in-between modules are underneath.

The usual picture used by Volkswagen to display the ID.3 (see 1st image of this article) is a 12-module Battery Pack (77 kWh). In this configuration, there is one module in each of the 12 “big boxes” that you can guess from the top cover (thanks to the embossment). In addition, there are 2 half-boxes with a smaller width. These 2 additional half-boxes contain all the Electronics (the BDU + the BMS). This electronics needs to be on the same side of the Pack as the multiple connector to keep the logic of saving weight, cost and complexity.

Module organisation and question over the “semi-module-boxes” on the opposite side of the connector within the Sono Battery Pack

The Sono Battery Pack presents very similar embossments typical of the traces of the Battery separator modules. Nevertheless, you can observe that the Pack seems “up-side-down” as the “half-boxes” are on the opposite side of the connectors. I can find 2 interpretations but none of them makes sense to me:

One of the Boxes on the same side as the connectors is empty and does not contain a module but the power-electronics instead. This is actually how VW manages the small battery pack (58 kWh, 9 modules) architecture. But in this case, maintaining the semi-boxes on the other side (they are removed in VW’s small pack) would be very mysterious as they do not serve any purpose anymore…

the Power Electronics is stored on the opposite side of the connectors but in this case this would mean long useless cables to connect with the ports at the connectors

The top cover of the VW ID.3 also presents many lines that are in reality small rubber pads. Their role is to prevent the vibration and also any possible contact between the Battery Pack and the MEB Platform. The place of these lines is defined by the long middle structure that runs from the front to the rear of the MEB platform. Very interestingly you can see the same lines on the Sono Battery Pack except that the Battery Pack has been reversed (so the back of the picture in Sono would correspond to the front picture of the VW ID.3. It is very easy to count these lines as well as to identify their size all over the 2 covers (ES= ExtraSmall; S= Small; M= Medium; L= Long). As a coincidence the 2 covers present exactly the same marks (just reverse, a bit like connectors)…

Details about the enclosure of the Sono (left) and the ID.3 (right) Battery Pack

The VW ID.3 seals the top cover to the rest of the pack thanks to 23 bolts on the each side and 18 bolts both at the front and the rear. The number of bolts are of course not made randomly as they seal the Pack from EMC. Funnily, Sono made the exact same choice. Another coincidence is the very similar structure cut around these bolts as details on this picture. This “cut” is also not a random choice because underneath the cover is a gap filler that completely seal the pack and that needs to go around each bolt. Of course, Sono made the same choice and funnily it seems the exact same “lace-pattern”…

Another similitude is the number of fasteners to attach the Battery Pack to the chassis. To my knowledge the number of fasterners used by various OEMs is very different and depends on the structure of the chassis of each OEM. For example, a Tesla Model 3 uses 55 fasteners while a Porsche Taycan uses only 28. Here, both Battery Pack made the exact same choice with 30 fasteners and even more funnily they are at the same place (but once again mirrored)

Comparison of the external clips on the Battery Cover between the Sono (left) and the ID.3 (right) Batteries

My last point of comparison is about the external pins that are attached on the Battery Top covers…Usually the number and the place of these pins are defined by the platform on which you put the battery (for the ID.3, the MEB Platform). Once a again, it is very funny to notice that both Battery packs are the same (just mirrored).

Beyond mirroring features, it also appears to all light features in VW’s picture appear dark in Sono’s picture and vice versa.

Source of the Sono Battery Pack image: https://sonomotors.com/en/sion/battery/