Battery Show Europe 2021

Photo credit: Cecile Pera

Battery Show is the biggest event in Europe for Battery Technology and business in the Automotive Industry. The show is split between showcase / presentation and exhibition / Trade-show. This article summarises only the Trade-show part in terms of business and technology trends. Presentations and forum discussion are also very interesting and more focused on supply chain, gigafactory set-up and chemistry roadmap. This will be reviewed in another article. The Trade-Show was oriented towards technology development / industrialisation and direct B2B business as the current trend in the Automotive Industry.

General Impression and Overview

Despite COVID, the Battery Show Europe 2021 was hosted at the Messe Stuttgart (Germany) from the November, 30th to December, 2nd 2021 (3 days). This is the 4th edition of this big show dedicated to Battery business. Even if Lithium Battery business is very large, the Battery Show must be taken as “Battery for Electric Vehicles” for the Automotive Industry. Around 500 exhibitors were exhibiting their innovations and products.

Globally, the Battery Show was really excellent with tons of new products presented, interesting discussions, major players and business opportunity. The atmosphere was joyful and full of excitement as this is the biggest European show and one of few in Europe during the pandemic.

If you imagine the exhibition of Battery Show as a sort of congress with major OEMs presenting their latest Battery development or showcasing their EV-platforms or Battery packs, you are mislead… Battery Show is a professional exhibition made by Battery players for Battery business with the objective to present detailed technologies that are usually unknown of the general public, such as Battery disconnectors (EV36), Battery housing (EV33), Compression Pads (EV17), etc.

Who attended the Battery Show Exhibition?

With more than 400 company booths and thousands of visitors, the Battery Show was definitively worth attending. You could find all players involved in Battery business from machine and tools needed to manufacture Batteries to final Engineering and Battery Pack assembling. There was also a large variety between very small startups and big players. Attendance was a mixture of very experienced/expert developers and complete newbies or business / investors curious to know more about the business and the trends or searching for contacts and partnership.

Pouch Cells from CUSTOMCELLS. Image credit: Cecile Pera

It is important to understand that the way the general public understands Battery development is very narrow. Usually people imagine Battery Technologies to be reduced to Cathode chemistry and large Battery packs developed by car manufacturers. Maybe paradoxically for you, there was none of these players at Battery Exhibition. This means that there were no OEMs (no Volkswagen, Porsche, Mercedes, Renault, Hyundai, etc.) but also nearly no major Battery cell suppliers: only Panasonic and CUSTOMCELLS (producing for Porsche from 2024 in a JV with them) were present but other players such as LG, SDI, SK Innovation…did not have a booth.

Nevertheless, very big/well-known companies in the Automotive industry were there such as:

3M, Dupont, Henkel… (chemical components)

Amphenol, TE Connectivity (connectors)

BorgWarner, MIBA, Oerlikon (Tier One supplier)

Dassault Systėmes, Gamma Technologies… (Battery modelling)

Fraunhofer (Research Institute)

Liebherr, Mitsubishi Electric, TRUMPF… (manufacturing / automatisation)

etc.

Please note that because of the COVID-december peak, all the British companies have cancelled participation at the last minute (Lotus Engineering, Danecca,…)

Main Technology Trends

It is very hard to summarise the main trends. Globally, my impression is that the Battery development is still at an early stage with tons of options and new players. It is important to understand that all these technologies are intricate and the development of a new sub-technology can act as an enabler for another major technology. For example, the development of new Thermal Interface Materials (EV40) can boost the development of Cell-to-Pack (EV29).

Nevertheless, there are very big trends that must be highlighted:

Runaway detection and prevention: Recent Chinese Regulations (GB 38031-2020) impose that the Battery system does not catch fire within 5 minutes after the Battery cell thermally loses control (so occupants get a warning and can escape before the fire starts).

Thermal Management: This includes the cooling system (cooling plate, etc.) but also the connectivity (pipes, etc), the control (BMS…) as well as side technologies such as Thermal Interface Material, thermal pastes, etc.

Lightweighing: In particular for Battery housing with a lot of technology around new Composite material

Compactness: Similarly to lightweighing, Battery Pack developers want to save space at a high cost. Any connector must be as compact as possible so that the pack will be smaller (and so indirectly lighter)

Quick connector for Battery cooling for easy assembly/disassembly

Serviceability and easy assembly/disassembly: Talking to various companies, it is very clear that most OEMs are concerned about the risks associated with Battery maintenance in the future. With an homologation currently around 5-8 years and a threat to see an extension of guarantee Battery pack over more than 10 years in the future, the Automotive Industry seem to focus on technologies that could be easily assembled/disassembled by local workshops. Of course, this flexibility is also very useful for future recycling but it is far more than that as a lot of products offer the possibility to connect / disconnect different elements in the pack (such as electrical connection but also coolant pipes, accessibility to power electronics, etc.).

Manufacturing (robotics, assembly chain, welding, drying rooms, etc,): With the development of more and more Gigafactories in Europe, the topic is critically important to guarantee the best quality / cost (to be competitive against China) but also to anticipate the CO2-cost in the scenario of a CO2-controlled supply chain.

It is also important to talk about the missing trends. I was personally disappointed to see so few companies focussing on the business of recycling and Second Life, showing how late we are in these topics. Of course, the Talks and presentations were tackling the recycling problem, but in practice there is a shortage of solutions ready to work or at least proving this business is viable (compared to manufacturing more and more battery) for companies.

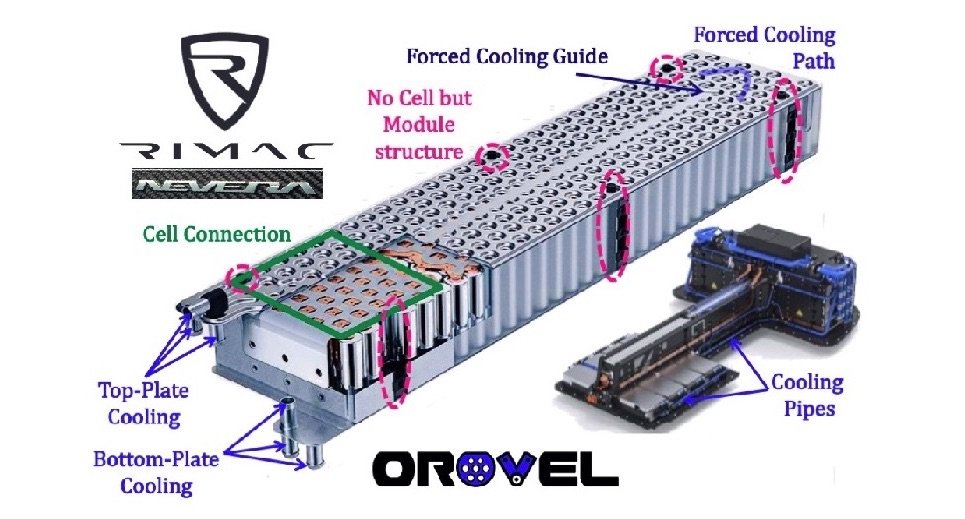

Cooling Plate Technologies

Batteries and Power Electronics generate a lot of heat that unfortunately contributes to their degradation. Naturally, Thermal Management appears as one of the key topic for OEMs. The cooling system and the cooling strategy is still a very open question with a multitude of options and a plethora of suppliers. As an overview of Battery cooling solutions, please refer to the OROVEL Battery card EV11. The dominant strategy is the cooling plate using water/glycol. Nevertheless, the way to distribute the coolant and the technology to embed the cooling plate is not fixed yet. At the exhibition, there were a lot of suppliers for Aluminum cooling plate but also some innovative solution such as cooling plates directly integrated into the casing.

Example of cooling plates: aluminum cooling plate to be placed at the bottom of the casing (left); example of coolant plate that could be pre-integrated in the casing (moulded in the composite), technology displayed by SABIC. Image credit: Cecile Pera

Example of Battery cooling plate integrated in the Battery casing. Image credit: Cecile Pera

Among the new products for Battery cooling, VOLTLABOR (MIBA Group) was presenting a sort of flexible cooling plate. It is made of 2 thin layers and can be inflated when cooling is introduced removing the need of gap fillers. The advantage is that it can be used in-between cells (in its serpentine configuration) or as a cooling plate directly inserted at the bottom of the module. It can be equipped with smart sensors. As seen on the video, the foils are very thin and the system is very flexible (it feels like plastic to me). The fluid connections are also directly integrated (see end of the video).

VOLTLABOR also develops its own Battery module and full Battery Pack (see the section Battery Packs).

If the Cooling Plate is the dominant technology with a lot of sub-technologies, there are still a few development around Battery Immersion cooling. Very few were presented at the show (only Ricardo and CARAR). They seem to me as early prototypes but something to monitor for “special applications” (such as Motorsport, High Performance cars or solutions for small Batteries in e-Motorbikes or special Hybrids).

Battery Cooling Circuits

Even simple parts such as pipes and connectors start to propose more technologies, targeting compactness, lightweighing but also production and maintenance advantages (such as the easy clip), leakage control, embedded sensors, smart components, etc.

Suppliers become - once again - more and more integrated solution providers rather than simple suppliers. For example, at Battery Show, ARaymond announced 2 recent acquisitions:

Castello, a company specialised in plastic tube extrusion allowing ARaymond to propose a complete system with both the connectivity and the piping

CGA Technologies, a company proposing high performing thermal cooling plates allowing ARaymond to propose a full solution for the thermal management of the full Electric Vehicles from the Battery to the full HVAC and eMotor cooling

Globally a good summary of this Thermal Management battle is the quote you can find on ARaymond website

‘To meet our customers’ evolving demands, we [believe] that agility and time to market are critical and that our customers are expecting COMPLETE SOLUTIONS”

Thermal management Business complexity: an example of available pipe and connectivity offer; Bottom-right: compact rapid clip for cooling assembly and desassembly; Top-right: Porsche Taycan complex cooling system involving the Battery cooling but also the full vehicle strategy.

At this point, if you are interested in Battery development but not convinced by the importance of parts such as cooling pipes and connectivity, it is important to remember that at the end, it does not matter to increase the Battery power density if you are not able to transform this into mileage. The cooling system enables not only to guarantee temperature protection but it is important to keep in mind that the cooling system is energivore on itself and that its consumption reduces the vehicle range. It is then very important for OEMs to have a strict control.

Safety Technologies

As explained previously, Thermal Runaway and Battery Fire are a very big concern for all OEMs. This is not surprising given how much safety issues have cost to some OEMs in 2021 (see for example the Hyundai KONA recall for 900M USD).

There are multiple aspects to Battery safety outside of the cell chemistry (LFP being safer than NMC for example). At the show, you could find for example Breathing and Venting systems (EV38) that are used to release any gas when thermal runaway is starting.

There are also Battery Disconnection systems (EV36) including BDU (Battery Disconnection Unit) or MSD (Manual Service Disconnection).

MSD (Manual Service Disconnection) for Safety (Maintenance and/or firefighter operation). Image credit: Cecile Pera

Runaway being a serious concern for all OEMs, multiple Technologies are focusing on limiting, dampening, preventing and/or anticipating cell runaway and/or thermal propagation. Among interesting Technologies, you find a lot of thermal Pads and coverage/wrapping for cells or for modules. For example, Isovolta is proposing a material combining (1) electrical insulation; (2) thermal conductive layer for optimised thermal management; (3) mechanical strength (which can be useful for Cell-to-Body (EV29). When looking at the product, it looks like a sort of gauze (thin medical fabric) that you can stick on cells or better on group of cells.

You also find a lot of suppliers proposing thermal Pads such as aerogels that allows to isolate one cells to another. This is of course efficient only for prismatic or pouch cells. For cylindrical cells other technologies are available such as Foam encapsulation proposed by H. B. Fuller. This technology is quite impressive as test with nail penetration shows that thermal runaway does not propagate to neighbours. This technology is already applied in some battery packs ;-)

Foam encapsulation by H.B. Fuller. Image credit: Cecile Pera

In addition to fire risk, electrical short-circuit is of major concern and many technologies aim at insulating electrical connections. Among examples worth mentioning: insulation coating on connectivity or encapsulation in plastic film.

Cables are generally a very hot topic and there were really many suppliers, some of them proposing developing very insulated and thin cables (again keep in mind lightweighting and space is a constant battle).

Insulation of electrical connection. On the left a part used by Mercedes, On the right high voltage insulation coating. Image credit: Cecile Pera

Last technology I want to talk about on Fire and Runaway safety is the Battery Housing itself. An interesting (and maybe unexpected) feature of a Battery casing in composite is that they can be very resistance to Fire. Do not forget that Aluminium melting point is about 660 degC. On the other hand, Thermoplastics can be very resistant to fire. For example, SABIC FR PP Compound H1030 was presented to resist more than 5 minutes (see Chinese safety standard) at 1000 degC.

SABIC Composite Battery casing. On the left: complete bottom housing. On the right: fire resistance. Image credit: Cecile Pera

Petrochemistry in the Battery business

Do you know who is SABIC by the way? SABIC is a Saudi Arabian company subsidiary of the biggest Petrol company Saudi Aramco (those who sponsor Formula 1). SABIC - to simplify - is the branch using all petrol components for “industrial applications”.

Actually, the general public does not pay so much attention to it, but a Battery is full of petrochemical products from separators, binders, thermal pastes, composites, etc. These products are generally relatively expensive because the number of players is limited. All very big names were attending the Battery Show including 3M, Henkel, Saint Gobain, etc.

Adhesives and sealing components (rubbers) are also components completely unknown to the general public, but that are very important when designing your battery pack. Tendencies are again the same: runaway protection, lightness and serviceability. It is not uncommon to find the commercial argument “resealable”.

Another class of chemical related products are Gap Fillers and other Thermal Interface Material (EV40) with or without silicons… Once again behind a relatively boring appearance (globally you do not see much more that a bunch of coloured Play Doo samples), there is a true strategic technology. Depending on TIM products, you can directly bond cells (easy assembly = cost advantage) but also facilitate heat transfers to the cooling plate, compensate for tolerance, dampen vibration, etc. These pastes for example are very important for the development of Pack-to-Cell and Cell-to-Body.

Thermal Interface Material. Photo credit: Cecile Pera

Battery Manufacturing

Gigafactories are very popular but behind the hype of the word there is a lot of automation and robotics. Battery manufacturing also means mixing, slitting, calendaring, drying, stacking, welding, etc. and, for these, the battery and automotive industry needs a lot of machines and tools. That is why it was a large part of the exhibition with big companies such as Liebherr (automation systems division), Mitsubishi Industrial, TRUMPF, etc.

There exists a fundamental difference between Batteries used in appliance and those used in the Automotive Industry. OEMs are under an enormous pressure in terms of warranty and longevity of their vehicles. When a smartphone has a warranty of 1 year, it is usually around 8 years for a car. Car manufacturers need to be able replace any part (requirement by law). One of the consequence is that the tolerance for failure and default is very strict in the automotive industry and this usually imposes very specific manufacturing processes.

This includes machines that can move and handle many toxic products (including very thin powders), calendering, machines that can target any default on various steps of the cells, the modules and the pack assembly, cooling and electrical connections, cleaning and more complex operation such as Plasma treatment that can be necessary to activate some chemical components on coating for example. This short video shows some examples of machines presented at Battery Show.

Electrical Connections

As you guessed, Electrical Connections are very important. This includes the busbars and other connections in-between the modules but also the way these connections are made which can be very different from one OEM to another. A lot of companies were presenting their know-how. For example, welding of Al/Al, Cu/Cu and/or Al/Cu materials with laser. Here below are some photos made at the Battery Show on the TRUMPT booth. You can see Laser welding/contacting of busbar with similar and different material combinations, with different thicknesses at high electric conductivity, mechanical strength and low spatter formation.

Behind these connections, weldings, busbars, etc. there are also a lot of technologies involved. The photo here below is an example of a connection by TE connectivity at Battery Show. These connections are important not only for Battery usage itself but also for the charging phase. Indeed these Module connections have to flow up to 600 Amp for several minutes during a supercharge cycle.

BCON+ bolt termination for Module-Module connection by TE Connectivity. Image credit: Cecile Pera (Left); TE Connectivity (Right)

Similarly to composite casings, aluminium battery housings start to pre-integrate battery cooling plates inside, at the bottom of the casing itself by extrusion or other techniques. This technology is pushed simulatenously by various big metallurgy companies such as Constellium in collaboration with Impression-Technologies.

Metallurgy groups are highly involved in the Battery business. Nevertheless, in order to keep the business and to increase their margins, they are also obliged to developed innovative solutions to become “technology provider” rather than just “metal part supplier”. This becomes even more crucial because Battery composite housings are pushing for lightweighing.

Gentherm eCCB (ECU integrated Cell Connecting Boards). Image credit: Cecile Pera

Another major trends is to be able to include smart components / electronics in the Cells / Modules connections. This allows including the possibility to embed sensors in the connectivity. For example, on this photo, you can see the integrated cell sensors by Gentherm allowing to measure the SOH (State of Health), the SOC (State of Charge) and the resistance of each cell of a Battery module.

Battery Packs

Finally, we can talk about the EV Battery which correspond to the “final product” to be used in a vehicle. In this case, we understand the word Battery as “Battery Pack”. As explained in the introduction, there was no OEM showing their Battery packs but of course some pack makers and/or suppliers were displaying their know-how with some customer examples. Not a lot of in-production Battery pack were shown and even less were showing how they were made.

TRUMPF had a nice display showing different part of a Battery Pack. On this video, you can see the Battery housing (bottom and top cover) that is obviously not composite here… You can also see how the cooling plate is inserted at the bottom of the modules and also how the connections are running on top of the Modules. Please note that at the top of the Pack, the orange box is a Manual Service Disconnection (EV36).

Several companies working on “special” applications were exposing at Battery Show. For example, XeroTech had an amazing Battery pack developed for off-road applications such as mining Vehicles. The Hibernium Battery System is a modular pack that can be adapted to various heavy duty vehicles. Packs can go from 20 up to 300 kWh!

VOLTABOR was also showing a Battery Pack for a bus application (I love the logo windows to show up the module inside!).

Webasto was explaining how they create a “super pack” by linking multiple Battery packs through their “Vehicle Interface Box”. Applications are Commercial Vehicles: Trucks, Buses, Off-Highway, etc.

Left: Battery Pack from VOLTLABOR; Right: Battery Pack from BOLD, Image credit: Cecile Pera

BOLD, a Spanish / UK company, was showing a Battery pack in a carbon casing for eVOLT and aviation applications. Some High Performance and Racing Battery Pack developers were also present. The booth of PODIUM was particularly amazing showing different Battery Packs for High Performance and racing applications.

Conclusion and Take Away

Battery Show Europe is an excellent Exhibition to attend to. The 2021 edition was a good sneaky peak at technologies under development and trends. There were a lot of exhibitors with really many players from big suppliers to very new startups. From a technology point of view, it is difficult to conclude what will be the winners in the coming years, because there are not only a lot of competition in-between companies but also in-between technologies.

Some technologies may not be the favourite for today but anything new (like a new cooling system, a new way to pack (cell-to-pack), new connections can quickly change everything as all these technologies are highly intertwined.

The “value” of a Battery technology is today measured with 2 main criteria:

The ratio cost / km range

Compliance for Runaway and Battery Fire standards

For sure, the business is now full of opportunity but also very risky because there will be big winners and big losers. Who will be there in 3 years time? OROVEL to always inform you on EV and Battery Technologies!